ArcelorMittal has commissioned technology provider Midrex Technologies to design a demonstration plant in Hamburg to produce steel with hydrogen.

The Luxembourg steel manufacturer revealed in April it was investigating the use of industrial-scale hydrogen in its production process as part of the company’s strategy to reduce CO2.

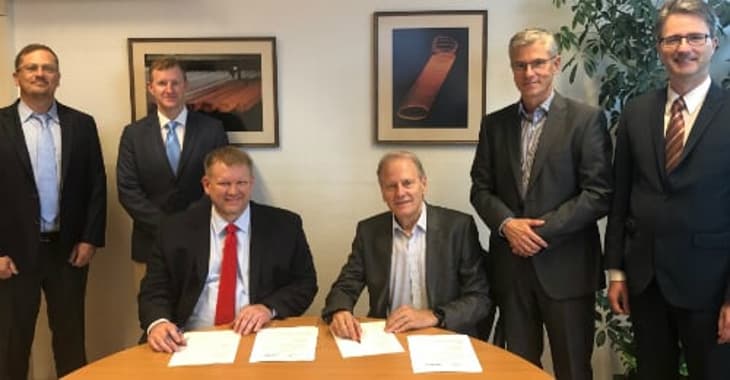

ArcelorMittal and Midrex Technologies have signed an agreement to cooperate on several projects, the first to demonstrate in Hamburg the large-scale production and use of Direct Reduced Iron (DRI) made with 100% hydrogen as the reductant.

In the coming years, the demonstration plant will produce about 100,000 tonnes of direct reduced iron per year – initially with grey hydrogen sourced from natural gas.

... to continue reading you must be subscribed