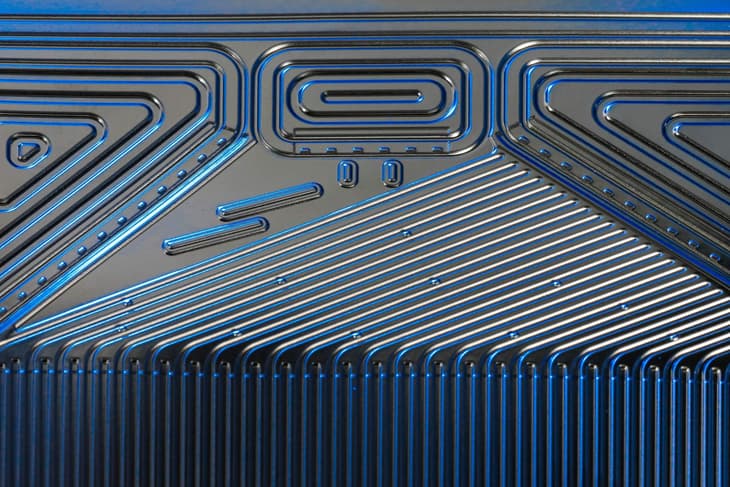

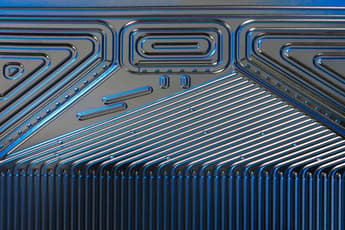

Cell Impact has received an order worth SEK 5.3m ($616,000) for its flow plate tooling and flow plate prototype production for hydrogen fuel cell production.

The order is set to be delivered in the third quarter of 2021 and is considered a continuation of earlier established activities in Japan as part of the cooperation with NKC Japan.

Read more: Cell Impact expands in Japan

... to continue reading you must be subscribed