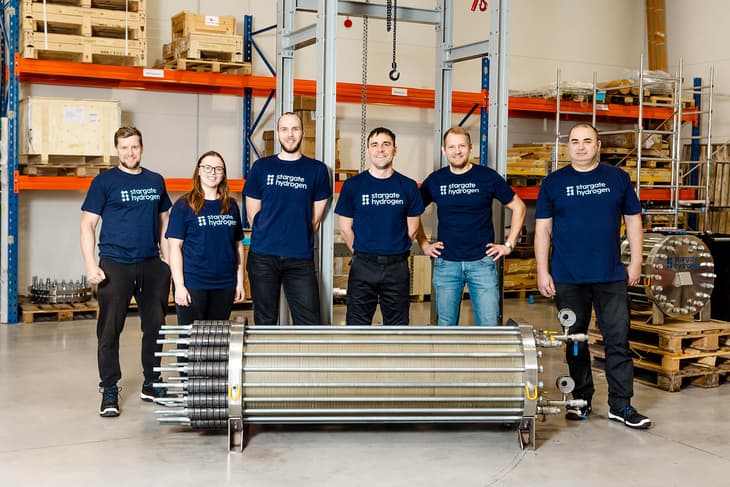

Estonia’s Stargate Hydrogen is set to officially launch its alkaline electrolysis stack, slated to have 80% stack-level efficiency.

The company revealed its European-manufactured “Stellar 100” stack, claimed to be among the “most efficient” stacks for green hydrogen production on the market, will be launched at the World Hydrogen Summit in Rotterdam next month (May 2024).

Jointly developed with European suppliers, the stack was tested by the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), revealing high levels of stack-level efficiency.

... to continue reading you must be subscribed