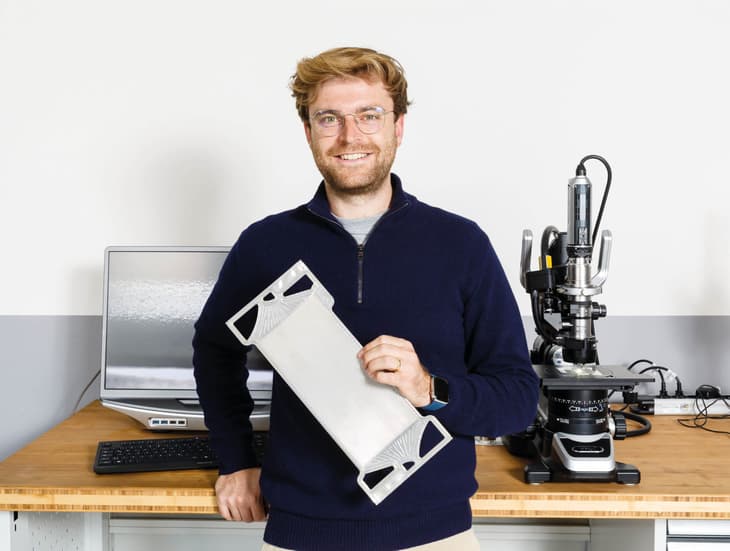

Delving deeper into electrolyser and fuel cell technology, H2 View caught up with German bipolar plate manufacturer, CellForm and its CEO, Simon Brugger. Aiming to become one of the leading suppliers for bipolar plates, CellForm intends to achieve three-digit million revenues by 2030.

Its production technology is expected to generate minimal cycle time, with its process allowing it to form, weld and test plates in ‘industry leading time’. CellForm also received the 2022 Energy Globe Award Germany for its manufacturing capabilities, and more recently the VR Innovation Award for SMEs 2023. In other major news, Albert Weber also acquired a ‘major stake’ in CellForm as a strategic investor.

Let’s start by telling us how the bipolar plates sector is faring, and how the technology is developing and helping to drive the durability and efficiency of hydrogen applications?

In recent times, the bipolar plate as a component in hydrogen stacks has seen significant progress in terms of durability and efficiency. It’s now widely recognised in the hydrogen industry that both durability and performance are fundamental aspects to address in hydrogen applications.

... to continue reading you must be subscribed