Companies pivoting towards hydrogen is something H2 View readers will be no stranger to. From oil and gas majors viewing hydrogen as the future, to the truck OEMs looking to introduce new powertrains into their drivers, many are looking to the energy carrier as a sustainable solution to future-proof their businesses.

A small number, however, have a history quite as entrenched in the technology that would become the natural home for hydrogen as Connecticut, US-based FuelCell Energy (FCE).

Founded by fuel cell pioneer Bernard Baker and battery expert Martin Klein in 1969, the company started life as the Energy Research Corporation to focus on fuel cells and rechargeable batteries.

Jason Few © FuelCell Energy

Originally using natural gas in its fuel cells, now President and CEO of almost five years, Jason Few, told H2 View, years of research drove the company to follow a “real opportunity” to use fuel cell technology as a way to deliver continuous baseload power in a cleaner and more efficient way.

“It was through that decision that the company stopped doing some of the other research around battery technology and then really focused on fuel cells,” Few explained. “We commercialised our first fuel cell product in 2003 which was sold to the Kirin Brewery Co. in Japan.”

At that time, Kirin had an anaerobic digester (AD) at its site. The new FCE System used biofuels produced from the AD to produce electricity and steam which was used to sterilise bottles for the beer, which the CEO believes was a good start to showcasing the flexibility of its platform.

Built on a molten carbonate technology, the platform has always allowed for a hydrogen blend of up to 50%. But, having added solid oxide technology to its arsenal in 2018, the platform’s flexibility has opened the door for what Few considers a “super-fuel.”

Switching on the hydrogen plug in

Few said the use of the word ‘platform’ is “very intentional” when talking about FCE’s technology. Using an enterprise software analogy, he explained that while one customer might purchase SAP for one purpose, another could use it entirely differently.

However, if one customer needed to use a new function, there isn’t any need to purchase additional software. The function is already written into the platform and ready to be switched on. “Our technology operates in the same way,” he remarked.

“Solid oxide has expanded our platform capabilities to produce and use hydrogen…The move to hydrogen was really more around market and timing, and when we thought that the opportunity was going to develop, because the fuel flexibility capability was something that we were very comfortable with.”

Now, the FCE platform incorporates technologies to deliver microgrids, carbon recovery, carbon capture and hydrogen production and use, while all being built in the same factory.

“We think there are our significant opportunities across the energy transition,” Few said. “Distributed power, distributed hydrogen, electrolysis, and long-duration energy storage. And this platform gives us the ability to do all four.”

The last opportunity is the most prominent for FCE. Despite scepticism over efficiency losses in converting green electrons to molecules, Few said one of the biggest benefits of using hydrogen for energy storage was due to that fact that it is “regenerative.”

“[Hydrogen] can be produced locally and stored in massive quantities,” he added. “As we continue to drive further penetration of intermittent technologies, you need a way to firm up energy capacity, and we think hydrogen is a way to get that done.”

And the company’s reasoning for choosing solid oxide as its fuel cell and electrolysis technology further plays into combatting efficiency concerns.

The CEO told H2 View, “If you look at PEM or alkaline technologies, the efficiency of converting electricity and water to hydrogen is anywhere between 60 and 65%. We’re 90+% coming out of the box.

“Then if we had a source of process heat that could be used, we’re at 100% electrical efficiency.

“All of the capital costs, regardless of technology, are relatively equal at scale. But if we have a 20-35% advantage, we’re using significantly less electricity. That efficiency is really important. In the long run, our technology wins because we’re going to produce the cheapest kilogramme of hydrogen.”

Solid oxide fuel cells and electrolysis are high-temperature alternatives to PEM and alkaline. Using a solid material as the electrolyte, electricity splits water under temperatures of up to 800oC. The temperature can significantly reduce the electrical energy required, making it more efficient than low-temperature alternatives.

Even now, Few told H2 View, “Research remains core to our DNA.” In November 2023, FCE announced a partnership with technology giant IBM to further extend the life of its fuel cells using AI.

He said the accelerated life testing process is very time consuming. Using AI, the pair will hope to “fundamentally change” the way FCE looks at testing its products, so it gets answers sooner and stronger conviction on those answers.

“We’re really going to be focused on life extension” he said. “We’ve done a good job of that already. When we first launched the product, we had a three year stack life. We’re now at seven, but we have a strong belief that we can do much better than that.”

Home state developments

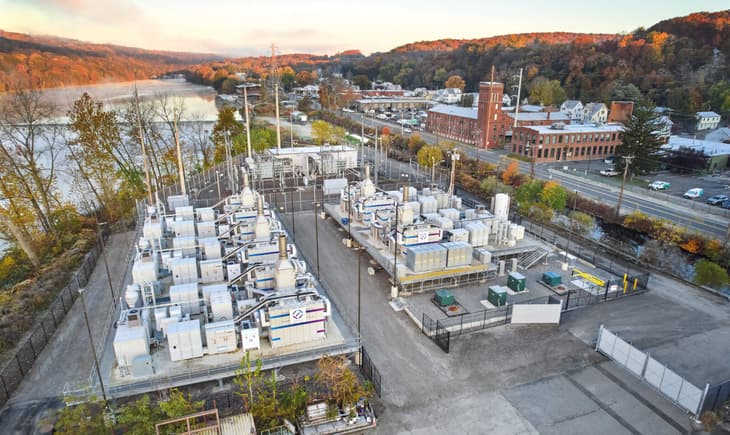

Late last year (2023), less than 26 miles from its headquarters in Danbury, Connecticut, the company opened its latest fuel cell park in Derby.

Characterised by Few as a development that is “delivering reliable, clean energy to citizens and businesses” in the state, the 14MW installation uses 10 fuel cells – making it the “second largest in North America,” just behind its own 14.9MW site in Bridgeport, Connecticut.

14MW fuel cell park in Derby © FuelCell Energy

Situated on the outskirts of the city in New Haven County, on a former brownfield site on the banks of the Housatonic River, the site quietly generates power from hydrogen which is delivered to thousands of Eversource and United Illuminating customers through PPAs.

Within the state, fuel cells, alongside solar, wind, geothermal and more, are categorised as a Class 1 renewable energy source. In 2022, Connecticut passed the SB10 regulation, setting the target for the state’s electric grid to reach zero-carbon by 2040.

If we’re going to electrify everything, we need to use our most abundant regenerative resources, and hydrogen is the most practical approach for storing large amounts of energy

Few praised the “leadership role” of the state in recognising fuel cells. “Our policymakers realised that it couldn’t get to its goals without a baseload source of power. The state looked at what is the cleanest way to do that- fuel cells and nuclear – and the state had the foresight to make fuel cells Class 1 renewables,” he said.

He continued, “As we continue to build out the penetration of intermittent technologies, you need a long-duration energy solution. Batteries, whether you need four hours or six hours, are not enough. The only way you can add more back up is to continue to add more and more massive batteries. Once those batteries are depleted, you’re done.

“With hydrogen you can store it in the same way you store natural gas – in salt caverns, pipelines or pressurised tanks – it’s far more space efficient.

“We think that hydrogen is the right way to go for long-duration energy storage. And certainly, for producing baseload power reliably, using hydrogen is a far better solution than any mineral-based solution.

“If we’re going to electrify everything, we need to use our most abundant regenerative resources, and hydrogen is the most practical approach for storing large amounts of energy.”

‘The perfect trifecta’

Almost 2,500 miles away however, FCE, in collaboration with Toyota Motor North America, has delivered its inaugural Tri-gen project. Situated in the Port of Long Beach, California, the platform is capable of generating hydrogen, electricity and water.

Biogas from Californian landfills is reformed inside a carbonate fuel cell into hydrogen, which is then converted into electricity and heat through a fuel cell. Producing 2.3MW of power, 1.3 tonnes of hydrogen per day and over 14,000 gallons of water per day, Few called it the “perfect trifecta.”

Long Beach Tri Gen project © FuelCell Energy

Hydrogen is then used by Toyota to refuel its Mirai passenger car fuel cell electric vehicles (FCEVs) and the Class 8 heavy-duty trucks co-developed with Kenworth. All while, the water produced by the system is used to wash the vehicles.

“We do all of this on site in a way where the hydrogen demand is located, the clean energy is needed, so that Toyota achieved its environmental goals by having a Net Zero operating facility at the Port of Long Beach, where it imports more than 200,000 cars a year into the US,” Few remarked. “It’s a really compelling solution.”

Water remains a significant point of contention when discussing electrolysis. While this particular project is not utilising the green hydrogen production pathway, Few said recycling water where possible remains a priority to the company.

“We recapture water produced by a fuel cell and can reuse it in electrolyser, minimising the total amount of water that we’re going to need to produce hydrogen,” he explained. “We’ve thought about how to most efficiently utilise water in electrolysis mode. For example, our electrolyser is not water cooled, which significantly reduces the electrolysis water requirement.”

We took the solution exactly to where the demand is. I think that is an opportunity that frankly, the energy sector has missed

Aside from the innovative technology and secured off-take, the FCE CEO said the Long Beach project shows the benefits of creating localised solutions, such as the inherent avoidance of permitting issues often associated with hydrogen projects in the US.

He explained, “Rather than building an offshore wind project or a solar project in the middle of the desert that then require permits to bring high voltage transmission lines to the site, we avoided all of that.

“We took the solution exactly to where the demand is. I think that is an opportunity that frankly, the energy sector has missed…The energy complex continues to be stuck in this world where we need bigger and more central installations. That’s not the right answer. We think there’s an opportunity to really number up rather than scale up. We’re going to try to push the industry and encourage the opportunity around that.”

Getting hydrogen projects on the ground

H2 View has regularly covered reports detailing challenges in getting hydrogen projects through final investment decision (FID) and on the ground. However, FCE, with its growing number of installations has effectively tackled many of those issues.

When asking Few about how the company has navigated moving from R&D to commercialisation, he said FCE’s longevity is among its biggest advantages.

He explained, “We’ve been doing this for a long time. We have a lot of confidence in our technology, and we’ve continued to have R&D in our DNA. We’ve done a lot of work with the US Department of Energy (DOE), customers focused on long-term solutions to challenges, and a lot of universities.”

But he also believes the industry and indeed the world is now at a point where the acceptance of new, innovative technologies is beginning to rise.

“We’re at a point now where legislation and consumer sentiment are more accepting of the science and the opportunity of hydrogen,” Few said. “For us being in a position where we have a technology already commercialised, and in the process of commercialising our second, that gives us confidence to move more aggressively into this opportunity.”

Despite aggressive and ambitious moves to deploy, at the heart of each FCE project is a community engagement element, the CEO said. “We’re trying to help customers understand what our platform is about and really educate or remove some of the lack of knowledge or misperceptions about the energy industry.”

As another point of difference for the firm, Few said the platform can be deployed “in the densest urban populations,” due to the lack of moving parts, low noise levels, and the ‘cool factor’ because the platforms are cool to the touch.

“We operate at decibels lower than the sound level of a hair dryer in your home…Although I don’t have that problem,” he laughed.

Few explained he thinks about the environment in two vectors: what is happening today and what happens tomorrow. “Climate change happens to me tomorrow. Poor air quality happens to me today,” he said.

“Nobody wants to hear a constant noise from somewhere. No one wants their children to breathe poor air. Frankly, that’s gotten lost in the discussion a little bit. So, we’re trying to get people to understand that both today and tomorrow’s important.”

Part of that legislative shift Few mentioned is of course FCE’s home nation’s Inflation Reduction Act (IRA). With a potential of $3/kg of hydrogen up for grabs by clean hydrogen producers in the form of tax credits, the Act initially delivered a wealth of interest in the US market.

However, the Treasury’s guidance – with criteria known as the ‘three pillars’ – on how producers can receive the top tier credit, in the view of many, could prevent interest turning into actual production.

Under the guidance, electrolytic hydrogen producers will have to source electricity from renewables in the same regional grid that are no older than three years old at the time of production start-up. Furthermore, producers must match renewable electricity and electrolyser operation within the same calendar month until 2027 – and within the same hour from 2028.

Few said the goal of the IRA’s tax credit is to drive hydrogen adoption, but he fears the proposed guidance goes too far too soon.

“The initial proposed rules are perhaps jumping ahead to 20 years from now,” he said. “As a company, we’re okay with the objective of the three pillars, which is to make sure the hydrogen really is low-carbon, but we think this can be met with existing market tools such as renewable energy certificates. If government stays focused on reaching scale, the three pillars will take care of themselves.”

“Whether or not you believe, as a matter of policy, that the three pillars are required, we think this needs to happen over time. To create scale and bring down costs rapidly, you need a framework that’s going to be the most constructive around that.”

Aside from the regulatory challenges, Few told H2 View, FCE’s focus remains on how it grows and scale its technology, with a view to expand into global markets.

“We want to do that, so we actually deliver against our company’s purpose: enable a world powered by clean energy,” he said.

ELECTROLYSERS: UNLOCKING THE FUTURE OF HYDROGEN Join H2 View and sponsor FuelCell Energy for a deep dive into the world of electrolysers and how they are shaping the hydrogen industry in 2024.

Interested in understanding FuelCell Energy’s efforts in integrating hydrogen into their decarbonization platform?

Register now here.